Introduction to NCREE

Located on one of the most active seismic regions in the world,

Taiwan suffers from frequent earthquakes caused by the Circum Pacific Seismic

Belt. In fact, about twenty significantly strong earthquakes have been recorded

in the history of Taiwan. To compensate for this, earthquake hazard needs to

be taken into account in all civil engineering constructions to ensure sufficient

resistance against the shakes. The National Center for Research on Earthquake

Engineering (NCREE) was established in 1990. Since then, this institution has

worked endlessly to upgrade seismic resistant design standards for all constructions

and provides feedback to the engineering community through research and development.

It is hoped that through the coordinated activities of NCREE, the

enthusiasm to conduct high-quality research will be stimulated to bring out

the full potential of its participants. These activities will include the holding

of seminars and workshops on a regular basis in which knowledge can be advanced

and continually improved. In addition, special emphasis has been and will continually

be given to technology transfer to the engineering professions for enhanced

seismic-resistant designs.

Today, research in earthquake engineering has entered a new level

of interactive examinations between theory and experiment based on pure theory.

Secondly, seismic resistant design standards have been established to make research

results applicable in the engineering community. NCREE uses the prototype of

on-site experimental workstations along with integrated research projects, along

with the large simulation laboratory to perform related earthquake resistant

tests. It is the goal of the National Center for Research on Earthquake Engineering

to achieve breakthroughs on future research in the earthquake-engineering field.

Laboratory --

Tri-axial Seismic Shaking Table:

The

seismic simulator in the NCREE possesses 6 degrees of freedom to simulate earthquake

motion in 3 axes. Major earthquakes occurred in the world can be reproduced

by the seismic simulator in the NCREE.The size of the shaking table of the seismic

simulator is 5m X 5M and its mass is 27tons. Structural model with maximum payload

50 tons can be accommodated on the table. The shaking table is a box shaped

structure so that high bending and torsional stiffness can be achieved with

limited mass of the table.

The

seismic simulator in the NCREE possesses 6 degrees of freedom to simulate earthquake

motion in 3 axes. Major earthquakes occurred in the world can be reproduced

by the seismic simulator in the NCREE.The size of the shaking table of the seismic

simulator is 5m X 5M and its mass is 27tons. Structural model with maximum payload

50 tons can be accommodated on the table. The shaking table is a box shaped

structure so that high bending and torsional stiffness can be achieved with

limited mass of the table.

The

shaking table is driven by 12 hydraulic actuators 4 actuators for each axis.

The hydraulic power is provided by 2 electrical pumps and 3 diesel pumps which

offer a total flow rate of 1,235 gpm with a working pressure of 210kg/cm2, The

weight of the shaking table and the structural model is balanced by 4 static

supports.

The

shaking table is driven by 12 hydraulic actuators 4 actuators for each axis.

The hydraulic power is provided by 2 electrical pumps and 3 diesel pumps which

offer a total flow rate of 1,235 gpm with a working pressure of 210kg/cm2, The

weight of the shaking table and the structural model is balanced by 4 static

supports.

The reaction forces of the actuators are provided by the reaction

mass which is 16m (length) X 16(width) X 7.6m(height in dimension and about

4,000 tons in mass. In order to further improve the quality of the testing environment,

the reaction mass is isolated from the fixed foundation by 96 air springs and

80 dampers.

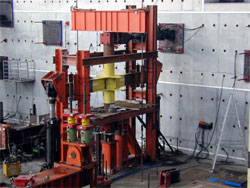

Reaction Wall & Strong Floor Testing System:

The reaction wall and strong floor provide the need for large-scale

structural and earthquake engineering experimental facilities. This intergraded

facility has the capability to perform large or full scale seismic tests by

using various experimental methods, such as traditional quasi-static tests,

cyclic loading tests and pseudodynamic tests.

The

L-shaped reaction wall in this center adopts the cell type design with stepwise

arrangement of wall heights including 15m, 12m, 9m and 6m and the respective

wall width of 15.5m, 15.5m, 12m and 12m.The reaction wall consists of two 1.2m

thick reinforced and post-tensioned concrete plates, which are parallel at a

distance of 2.6m, and was enhanced with a 0.4m thick reinforces concrete plate

in between at an interval of 3m. The strong floor was designed as a reinforced

concrete slab which has a size of 60 x1.2m thick. The specified compressive

strength of the concrete for both the reaction wall and strong floor is 350

kg/cm2.

The

L-shaped reaction wall in this center adopts the cell type design with stepwise

arrangement of wall heights including 15m, 12m, 9m and 6m and the respective

wall width of 15.5m, 15.5m, 12m and 12m.The reaction wall consists of two 1.2m

thick reinforced and post-tensioned concrete plates, which are parallel at a

distance of 2.6m, and was enhanced with a 0.4m thick reinforces concrete plate

in between at an interval of 3m. The strong floor was designed as a reinforced

concrete slab which has a size of 60 x1.2m thick. The specified compressive

strength of the concrete for both the reaction wall and strong floor is 350

kg/cm2.

There are 18sets of static hydraulic actuators and 6 sets of dynamic

hydraulic actuators in this laboratory.  Their

detailed characteristics are listed in the table. Five hydraulic hard-line ports

are appropriately located in the reaction wall and strong floor. These ports

provide for a total of 1325 gpm hydraulic power supply and return as a drain

line. The working pressure for the hydraulic system is 210 kg/cm2.

Their

detailed characteristics are listed in the table. Five hydraulic hard-line ports

are appropriately located in the reaction wall and strong floor. These ports

provide for a total of 1325 gpm hydraulic power supply and return as a drain

line. The working pressure for the hydraulic system is 210 kg/cm2.

The

seismic simulator in the NCREE possesses 6 degrees of freedom to simulate earthquake

motion in 3 axes. Major earthquakes occurred in the world can be reproduced

by the seismic simulator in the NCREE.The size of the shaking table of the seismic

simulator is 5m X 5M and its mass is 27tons. Structural model with maximum payload

50 tons can be accommodated on the table. The shaking table is a box shaped

structure so that high bending and torsional stiffness can be achieved with

limited mass of the table.

The

seismic simulator in the NCREE possesses 6 degrees of freedom to simulate earthquake

motion in 3 axes. Major earthquakes occurred in the world can be reproduced

by the seismic simulator in the NCREE.The size of the shaking table of the seismic

simulator is 5m X 5M and its mass is 27tons. Structural model with maximum payload

50 tons can be accommodated on the table. The shaking table is a box shaped

structure so that high bending and torsional stiffness can be achieved with

limited mass of the table. The

shaking table is driven by 12 hydraulic actuators 4 actuators for each axis.

The hydraulic power is provided by 2 electrical pumps and 3 diesel pumps which

offer a total flow rate of 1,235 gpm with a working pressure of 210kg/cm2, The

weight of the shaking table and the structural model is balanced by 4 static

supports.

The

shaking table is driven by 12 hydraulic actuators 4 actuators for each axis.

The hydraulic power is provided by 2 electrical pumps and 3 diesel pumps which

offer a total flow rate of 1,235 gpm with a working pressure of 210kg/cm2, The

weight of the shaking table and the structural model is balanced by 4 static

supports. The

L-shaped reaction wall in this center adopts the cell type design with stepwise

arrangement of wall heights including 15m, 12m, 9m and 6m and the respective

wall width of 15.5m, 15.5m, 12m and 12m.The reaction wall consists of two 1.2m

thick reinforced and post-tensioned concrete plates, which are parallel at a

distance of 2.6m, and was enhanced with a 0.4m thick reinforces concrete plate

in between at an interval of 3m. The strong floor was designed as a reinforced

concrete slab which has a size of 60 x1.2m thick. The specified compressive

strength of the concrete for both the reaction wall and strong floor is 350

kg/cm2.

The

L-shaped reaction wall in this center adopts the cell type design with stepwise

arrangement of wall heights including 15m, 12m, 9m and 6m and the respective

wall width of 15.5m, 15.5m, 12m and 12m.The reaction wall consists of two 1.2m

thick reinforced and post-tensioned concrete plates, which are parallel at a

distance of 2.6m, and was enhanced with a 0.4m thick reinforces concrete plate

in between at an interval of 3m. The strong floor was designed as a reinforced

concrete slab which has a size of 60 x1.2m thick. The specified compressive

strength of the concrete for both the reaction wall and strong floor is 350

kg/cm2. Their

detailed characteristics are listed in the table. Five hydraulic hard-line ports

are appropriately located in the reaction wall and strong floor. These ports

provide for a total of 1325 gpm hydraulic power supply and return as a drain

line. The working pressure for the hydraulic system is 210 kg/cm2.

Their

detailed characteristics are listed in the table. Five hydraulic hard-line ports

are appropriately located in the reaction wall and strong floor. These ports

provide for a total of 1325 gpm hydraulic power supply and return as a drain

line. The working pressure for the hydraulic system is 210 kg/cm2.